What’s the difference between Ultrasonic Welding vs. Conventional Welding? Read the article to know its differences, pros, and cons.

3 Tube Sealing Applications for Air-conditioning and Refrigeration

Tube sealing machine is being used in refrigeration, pharmaceutical, and chemical industries. Plastic and laminate tubes are sealed using high-frequency ultrasonic vibration. The vibration causes the tube to heat and melts the plastic material. Ultrasonic tube sealing has many advantages compared to other methods, such as heat sealing. It has lower energy consumption, is faster, and produces a more eye-pleasing shape.

TECH-SONIC’s Tube sealing machines are used to seal tubes often found in refrigeration systems. Learn the three tube sealer applications that are useful to refrigerator and HVAC manufacturers.

Three Ultrasonic Tube Sealing Machine

US-3620TS-EX

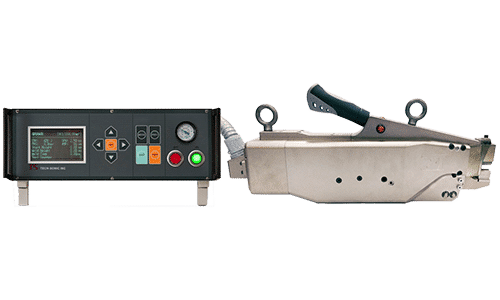

Since the Kigali Agreement limits the use of hydrofluorocarbons (HFCs) due to their high global warming potential, flammable refrigerants are better. TECH-SONIC’s US-3620TS-EX tube sealing machine can work safely with hydrocarbons, hydrofluorocarbons, and ammonia refrigerant alternatives. It is a one-step weld and cut process with no heat applied and no consumables needed. It has a maximum weld force of ~3,000 Newton.

The US-3620TS-EX tube sealing machine is Explosion-Proof Certified for operations using flammable gas. These certifications include Ex-Zone 2, Class 1, and Division 2 Certification. Its ultrasonic application replaces conventional brazing, which is incompatible with flammable HC alternatives. Its safety purge system removes trapped gas from the weld actuator. This process begins before electric startup and remains active while powered up. This results in the elimination of any unsafe gas accumulation.

This tube sealing machine features an ergonomic weld head design to better access whatever is being sealed. It has dedicated cooling for optimum thermo-management of sonotrode. The back cover is easy to remove for tooling changes. The Smart Program Setup allows for a more consistent day-to-day measurement, and faster calibration. For security and backup, it has a versatile password-based Access Control system. All operators have their profiles according to the level of access granted by the management and can set to demand a barcode scan during every weld. This ensures that the weld results for every product are associated with the product’s serial number.

Read the article managing flammable refrigerants. Learn how ultrasonic tube sealing machines can manage and reduce explosion risk.

Falcon-KN

The Falcon-KN model is our cheaper (economy) ultrasonic tube sealing machine. It provides a spectacular solution for a large array of ultrasonic metal tube sealing applications. The greatest weld force is ~5,200 Newton. This tube sealing machine produces a strong, solid-state bond that is clean and consistent. It’s easy-to-use, with low maintenance and tooling costs. It is also time-efficient, with up to 20 welds per minute, and quick-change tooling in under 3 minutes. This model is inexpensive since one tooling set (horn and anvil) produces ~40,000 welds!

Falcon-KN features the same ergonomic weld head design, with a narrow frontend to allow better access to tight places. Dedicated cooling for optimum thermo-management of sonotrode also comes with this design. This ultrasonic tube sealing machine has an easily removable back cover with just 6 screws to unscrew. It also has an adjustable main cable assembly which can be hanging down or straight upwards at the elbow.

US-3620TS

TECH-SONIC’s US-3620TS tube sealing machine is a more robust solution to your tube sealing needs. This machine is also a one-step weld and cut process. Like the other tube sealers, it is easy to use with low maintenance and tooling costs. It can detect the energy, time, and thickness offsets needed to weld.

This model can weld copper or aluminum tubes with 2-12 mm diameters, and wall thickness of up to 1mm. Its greatest weld force is ~3,000 Newton. It has the same features as the US-3620TS-EX tube sealing machine such as the ergonomic weld head design, easily removable back cover, smart program setup, security and back-up, and barcode compatibility.

Whatever your refrigeration and air-conditioning needs, TECH-SONIC has it. This company has been an innovative leader in the field of “Ultrasonic Metal Welding” since 1996. It has a wealth of knowledge in applying tube sealing solutions for a diverse range of applications. Thus, creating spectacular success in various production environments.

Facebook

Twitter

Email

Featured Products

Ultrasonic Tube Sealer (Explosion Proof)

US-3620TS-EX

Ultrasonic Tube Sealer

US-3620TS

Ultrasonic Tube Sealer (Economy)

Falcon-KN