Ultrasonic Tube Sealer

US-3620TS-EX

We are the Main Global Supplier of Tube Sealing System for:

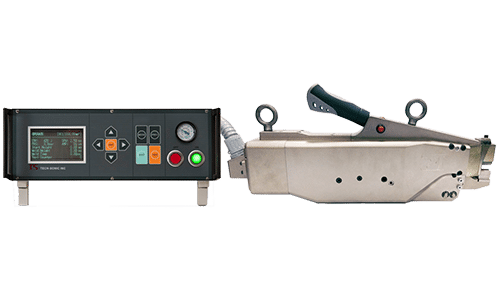

US-3620TS-EX

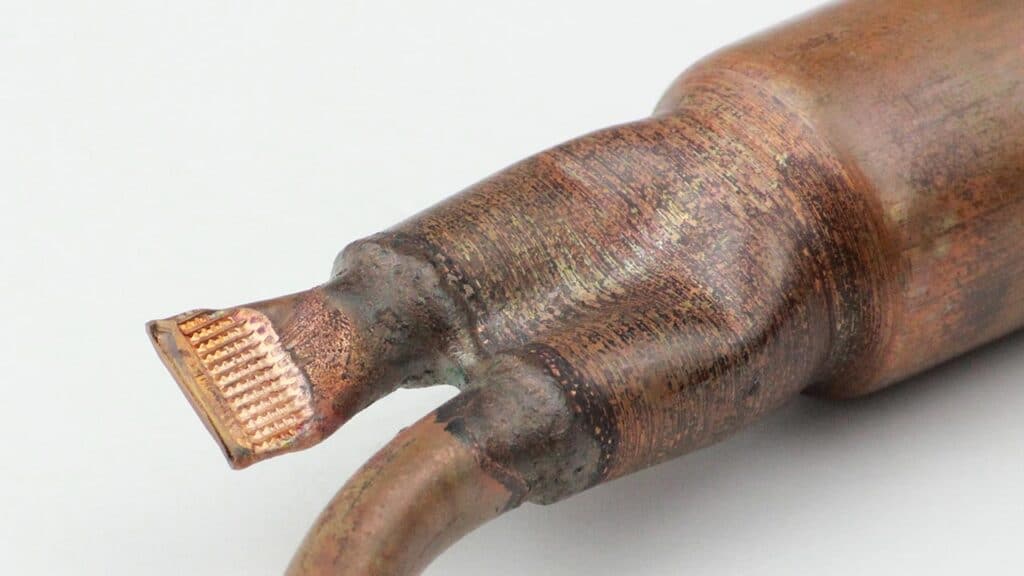

The TECH-SONIC explosion proof ultrasonic tube sealer, model 3620TS-EX is used primarily in applications that pertain to refrigerator manufacturers and HVAC manufacturers. The Ultrasonic welding process replaces traditional brazing methods that are incompatible with flammable gas. The US-3620TS-EX ultrasonic tube sealer is used to seal charged copper tubes in accordance with the Kigali agreement (by law). The US-3620TS-EX is Explosion-Proof Certified for operation with flammable HC alternatives, creating a spectacular solution for the phaseout of Ozone- Depleting Substances (ODS). These certifications include Ex-Zone 2, Class 1, and Division 2 Certification.

Ultrasonic Welding Advantages for Tube Sealing

Ultrasonic Welding for Tube Sealing applications is advantageous due to the following factors: it is a pure metallurgical bond for many non-ferrous materials, ability to weld dissimilar materials, fast cycle time, and consistent weld quality.

Features and Benefits of Ultrasonic Welding for Tube Sealing Applications

- Simple one-step calibration using 3mm pin gauge

- Precise measurement of pre-weld and post-weld height

- No need for outside consumables used in current crimping and soldering methods

- Tooling can last over a million cycles with small wire splices

- Operates at 20 times less energy than resistance welding

For more technical information, please download our brochure.

Need a cheaper solution? See our Falcon-KN model

Need a more robust solution? See our US-3620TS model

Ultrasonic Tube Sealing Machine

US-3620TS